HB Clay Resources Sdn Bhd commenced operations in August 2023 where its factory located in Sungai Petani, Kedah.

Benefit from more than 12 years of expertise from the renowned HO BROTHER BRICKS

SUPPLY SDN BHD, we have earned a strong reputation in clay brick making industry.

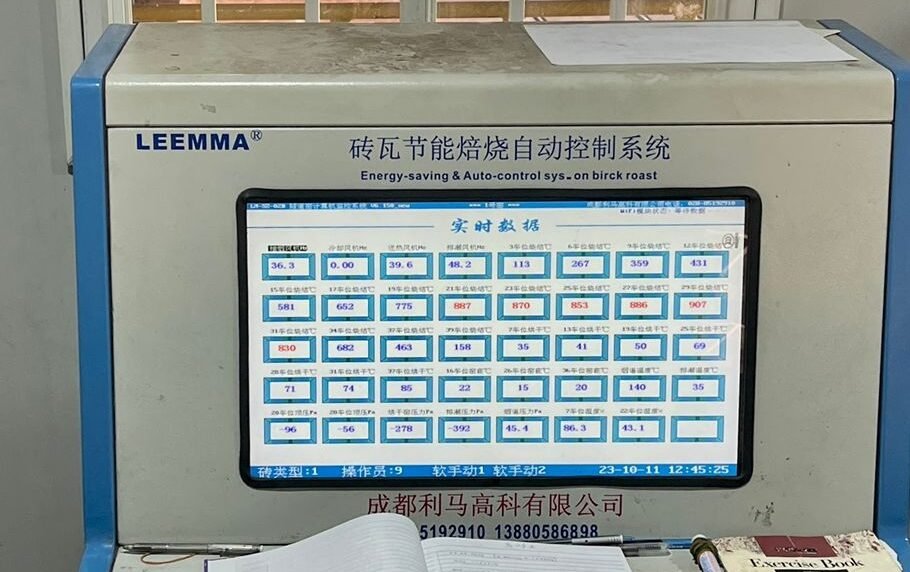

We employ the latest Kiln Roasting Technology from China, featuring an internal combustion technique which resulting in bricks with high compressive strength.

Currently, our factory produces 4 million pieces of bricks per month to meet the market demand. To ensure our brick quality can be consistently maintained, our trained personnel are frequently deployed to monitor and assist at various work sites.

Quality & Service Is Our Commitment !